JUTENDER

(Concrete Filling Detector)

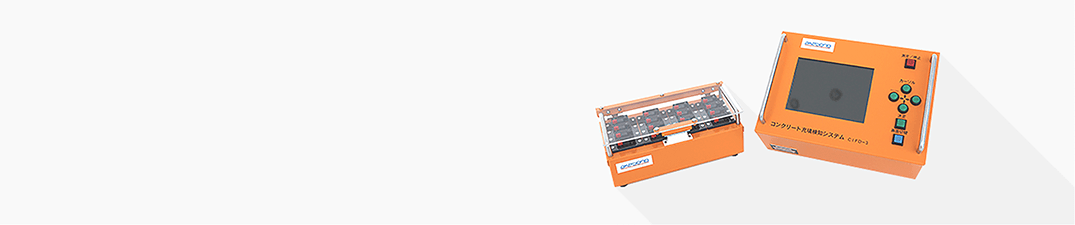

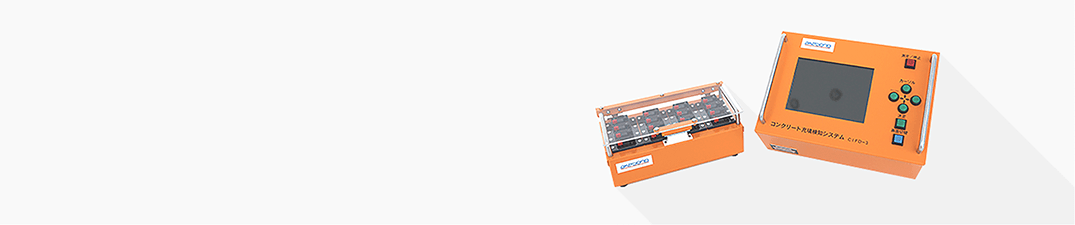

The “Jutender” is a completely new high precision concrete filling detection system developed using Akebono’s vibration analysis technology.

The system includes a small vibration device and a detection component. The later sends a signal that displays a red (air), green (concrete) or yellow (defective/water) image on an LCD screen that allows the viewer to determine if there’s still empty space to be filled. The data results are then transferred for storage and analysis to a personal computer, which gives ability to control the finishing time data etc.

Vibration device

Ministry of Land, Infrastructure and Transport Information System New Technology Registration number: KT-090011-VG (New Technology Information System : NETIS)

| Item | Specification |

|---|---|

| Model | CIFD-3 |

| Detection method | Detection of special frequencies by vibration device |

| Identification ability | Air, defective status (water), concrete, (various grout *please inquire with us) |

| Measurement channels | 16ch |

| Display | LCD monitor color display |

| Measurement time | About 0.5 seconds per 1ch |

| Sensor cable length | 5m, 20m standard (up to 50m with extension cable) |

| Sensor resistance (unimpacted) | 0.3MPa (water pressure) |

| Date feature | Internal clock: hours/minutes/seconds/month/day/year |

| Event recordings amount | Approximately 200 events |

| Output data format | Text format |

| Power | AC90V ~ 110V [Built-in internal data backup battery] |

| PC connection | Serial port D-sub (9 pin) |

| Operating temperature & humidity range | 0 ℃ ~ 40 ℃ 5 ~ 85% (non-condensing) |