Akebono's Corporate Philosophy & Mission

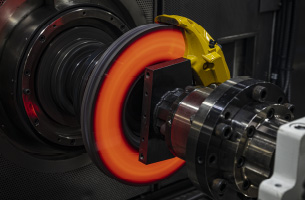

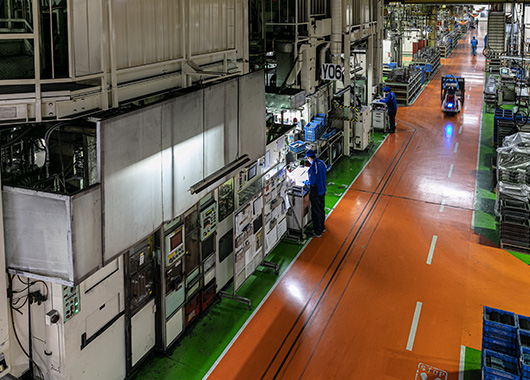

Realizing our mission as a comprehensive brake manufacturer, we aim to create a better future for all

Akebono's corporate philosophy was established in 1964. In the same year, the organization's in-house magazine “SEIWAKON” was established. The magazine continues to be published, and thus, our philosophy is widely understood and embraced by our associates to this day.

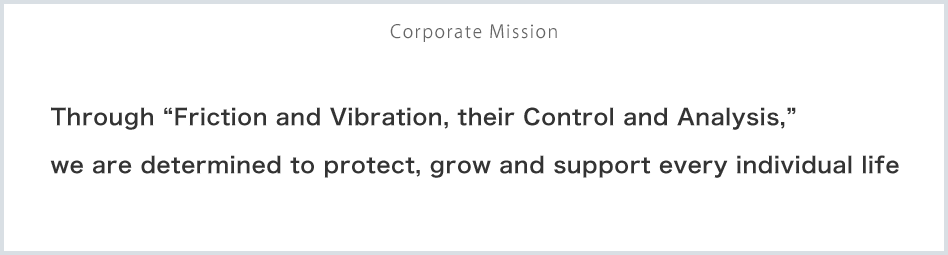

Our Corporate Mission was established in 1999 in recognition of the importance of laying out a roadmap for Akebono's future progress as a unified corporate group.

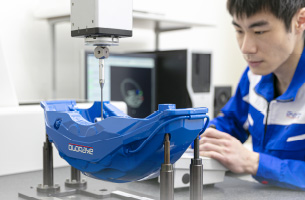

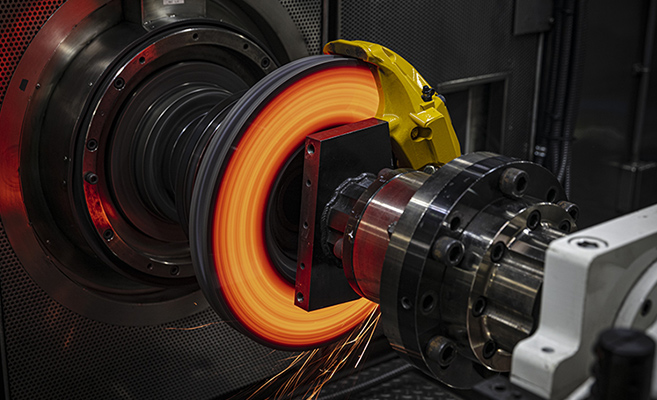

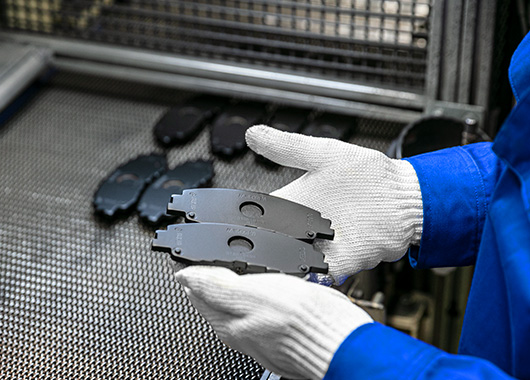

Akebono's core expertise is in the field of “friction and vibration, their control and analysis.” We deliberately place control before analysis in order to express our firm belief that it is Akebono's primary duty to promptly address and resolve the issues our customers are facing.

Our commitment to protection extends not only to human life. For Akebono, the phrase “every individual life” includes every single life-form on the planet, and thus, by extension, the global environment itself. Our Corporate Mission thus stipulates that we will create corporate value based on sound management in order to continuously protect and support all such life.

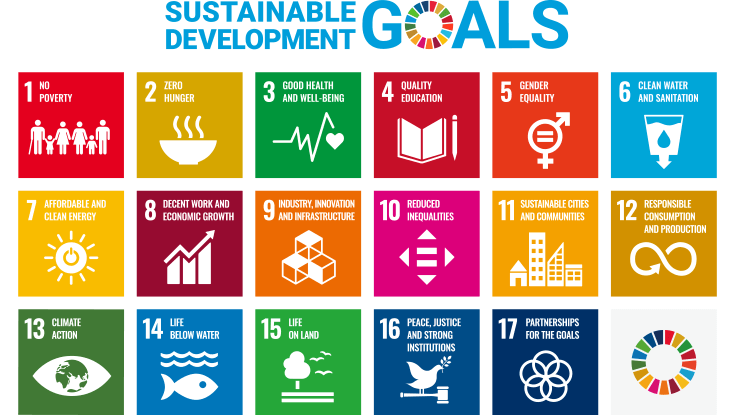

By translating akebono's Corporate Mission into reality, we shall contribute to the development of a sustainable society.