Initiatives in Design and Development

Developing Products Free of Environmentally Hazardous Substances

The use of brake friction materials generates brake dust. In Europe, Euro 7 has been established as a new regulation replacing Euro 6, which also regulates wear particles from brakes and tires in addition to vehicle exhaust emissions. Recently, there has been a growing movement toward PFAS regulations.

Akebono considers the suppression of wear particles generated from brakes as a significant technological challenge and is actively engaging in the development of technologies to identify the factors causing particle generation and reduce their emission levels. In addition to addressing environmental regulations, we are working to reduce environmentally harmful substances by promoting the replacement of materials of concern, which are deemed to have significant impacts on humans and the environment, with alternative materials.

Development of Brake Pads that Reduce CO2 Emissions by 50% during the Manufacturing Process

Akebono is developing next-generation brake pads that can halve CO2 emissions in the manufacturing process compared to conventional brake pads. By optimizing the composition of raw materials and refining the manufacturing process, we have successfully lowered energy consumption by partially eliminating and consolidating heating processes, which are typically major sources of CO2 emissions.

This innovative manufacturing method not only enhances work efficiency but also reduces production time by more than 50% compared to conventional processes. Additionally, it reduces material dust and odor generated during processing, thereby alleviating the burden on the production environment.

Development and Promotion of Copper-Free Friction Materials

Copper-free brake pad

In the U.S. states of Washington and California, state laws have been enforced regarding restrictions on chemicals contained in automotive brake friction materials to prevent the impact of emissions of such substances on river and marine ecosystems. In the state of California, restrictions on copper have been enforced since 2021, and from 2025 onward, it is illegal to fit new vehicles with friction materials containing 0.5% or more of copper. Conventional friction materials have used copper to ensure safe and effective performance at high temperature. Akebono developed copper-free friction materials and started to market them for aftermarket products in 2007 and supply them as OEM parts to automakers since 2014. By combining multiple component materials, Akebono achieved the same performance as pads containing copper while keeping the cost at the same level.

Akebono will continue to comply steadily with laws, including Washington state laws going forward.

Development of Next-Generation Brakes Aligned with "CASE"

As technological innovation advances in the new areas referred to as "CASE" — Connected, Autonomous/Automated, Shared, and Electric — the concept of automobiles is undergoing a significant transformation. Akebono is actively developing next-generation brakes to adapt to these changes.

Electromechanical brake caliper

Electromechanical Brake Calipers

Electromechanical Brake Calipers employ an electric operating mechanism to press the disc brake pads. There is no need for hydraulic piping, making the vehicle lighter, which in turn improves fuel efficiency. They are also environmentally friendly because they do not use brake fluid, which must be properly disposed of whenever repairs are made. Another key feature is its high compatibility with the latest vehicles equipped with ADAS (Advanced Driver Assistance Systems), which automatically control the brakes.

Low drag caliper

Low Drag Calipers

Low drag calipers incorporate specially designed components to ensure that pad to rotor gaps are optimized at the micron level. This reduces brake drag due to contact between the pad and rotor when the brake is released, contributing to improved fuel economy.

Ceaseless Pursuit to Make Brake Components as Light as Possible

From 2007, Akebono supplied its brake systems to the McLaren Formula 1 racing team. To satisfy McLaren's requirements, Akebono developed technologies that improved the structure, materials, surface finishing and other aspects of its products and worked to enhance the reliability and stability of its brakes to the greatest possible extent, even pursuing a few thousandths weight reduction as well as high rigidity and outstanding cooling performance.

Striving to develop competitive brakes for use in Formula 1, the FIA World Endurance Championship, the FIA World Rally Championship and other prestigious motorsports, Akebono continues to achieve technological breakthroughs and reflects them in the creation of products for mass production. For example, Akebono’s weight-saving technologies help enhance fuel efficiency and thereby contribute to lower energy consumption for automobiles. The pursuit of weight reduction contributes to driving stability and fuel efficiency improvement of automobiles, while also helping to save resources. We are supplying mass-produced products incorporating these technologies to high-end car manufacturers in Europe.

We are also developing copper-free brake pads that comply with U.S. chemical regulations for high-performance vehicles. Additionally, to meet the Euro 7 regulations on brake wear particles in Europe, we are working on developing brake pads compatible with hard-coated brake rotors, which some automakers are considering adopting. Moving forward, we aim to expand the production of brake pads that combine both braking performance and environmental performance for mass-produced vehicles, while also advancing the development of environmentally friendly products in the field of high-performance vehicles.

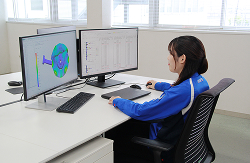

Technology to Control Noise and Vibration

When it comes to making brakes, finding ways to control the noise and vibrations that may make the driving experience uncomfortable for the end-user is of the utmost importance. Noise refers to the sound generated when vibration caused by the friction between the pads and rotors is transmitted through the calipers and resonates throughout the brake. There are various other phenomena that may affect driver comfort, and Akebono is working on measures to address "NVH"*, which makes for a less comfortable braking experience. Noise and vibration are affected by many factors, including driving conditions and previous travel, speed, brake temperature, material and form of components, and rotor wear. Countering these factors requires extremely advanced technology. To counter noise, which is particularly challenging, Akebono uses a computer simulation called Complex Eigenvalue Analysis. By reflecting various factors related to noise and vibration in the simulation to increase its accuracy, Akebono can implement countermeasures at the design stage before actually making the brake, thus reducing the number of prototypes needed and contributing to both energy and resource savings. Akebono is also addressing noise and vibration phenomena known as "groan" and "judder" by utilizing a database that compiles field data, bench test results, and past countermeasure methods, and working on the optimal design of brake components.

- *NVH: acronym for noise, vibration and harshness (vibration due to uneven road surface). Akebono refers to and approaches the various phenomena that affect braking comfort as "NVH".

Upgrading Ai-Ring to Secure Competitiveness in the Global Market

Ai-Ring

Akebono's proving ground, Ai-Ring, is one of the largest operated by an automotive parts maker in Japan. The facility was badly damaged in the Great East Japan Earthquake of March 2011. The high-speed circuit was subsequently restored in 2012, and in October 2016, we added various new types of test tracks, including a new winding road, a comprehensive rough-road evaluation track, and slopes, while also expanding its dynamometer testing facilities (brake testing machines) to prioritize safety from the design stage. This has enabled us to conduct comprehensive evaluations from bench testing to vehicle testing within the same facility, thereby speeding up our development.

It also enables a development flow that allows engineers to be involved in evaluation throughout the entire process, and we use it as a human resource training site to help employees deepen their knowledge about driving skills and vehicle construction and functions. In the automotive industry, as technologies such as electrification and autonomous driving are rapidly innovating in response to global environmental issues and the need to improve safety, Akebono aims to enhance its competitive advantage in development by cultivating brake specialists who combine a deep knowledge of vehicle construction and functionality with the sensitivity to swiftly respond to societal changes.

Additionally, we utilize a database that allows us to retrieve evaluation result history and NVH*-related information when needed. Akebono will continue to increase its evaluation capabilities by using actual vehicles and enhance its NVH analysis and simulation technologies as it actively engages in development of new products.

Moreover, the Company reused 100% of the trees that were cleared to construct the test course expansion, turning them into wood chips and spreading them on slopes to control soil erosion. In this way, we achieved zero-emissions. We also installed a 40 kW total capacity solar power generation system on-site. This will supply areas with facilities that use a lot of power, such as large dynamometers. In addition, some of the power will be stored to provide approximately 7 hours of power to a network server, fluorescent lighting, and power sockets within the office in the event of a power cut.

- *NVH: acronym for noise, vibration and harshness (vibration due to uneven road surface). Akebono refers to and approaches the various phenomena that affect braking comfort as "NVH".