Initiatives in Production

Initiatives to Reduce CO2 Emissions and Water Usage

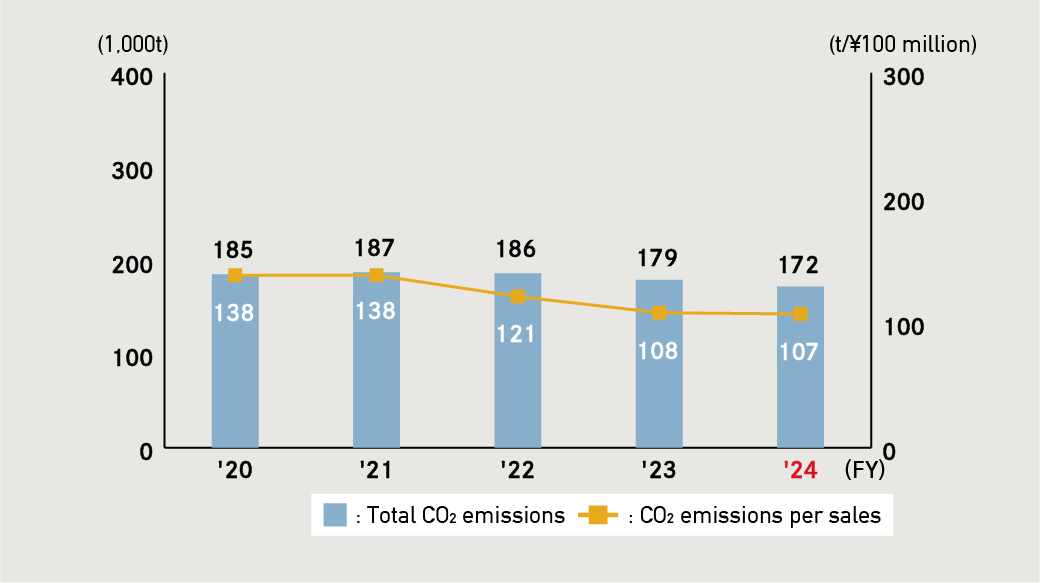

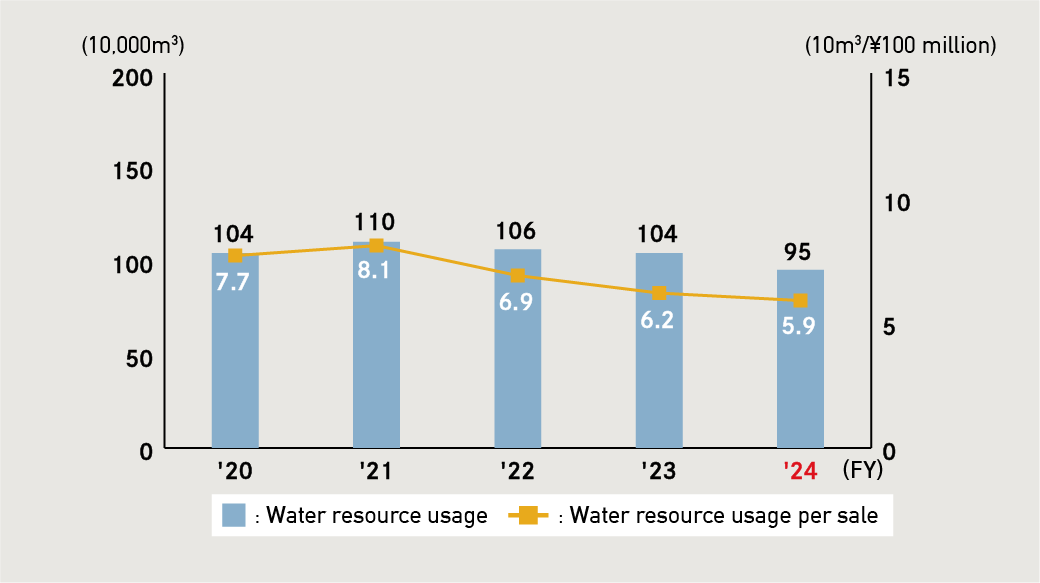

The Akebono Brake Group has been carrying out an energy and CO2 reduction project since fiscal 2007, improving onsite facilities at all sites to help reduce CO2 emissions and implementing energy conservation activities. Considering the importance of managing water to reduce usage, we have ascertained our water usage and continue to prioritize activities to reduce this.

The Akebono Brake Group's CO2 emission volume worldwide in fiscal 2024 decreased by approximately 7,000 tons from the previous fiscal year to a total of 172,000 tons-CO2 due to consolidation of production processes and reduction activities of standby power. Our water usage decreased from the previous fiscal year by 90,000 m3 to 950,000m3.

Furthermore, solar power generation that began operation in January 2024 at our headquarters, Ai-City, has contributed to a cumulative reduction of 130 tons of CO2 emissions.

Akebono will continue activities to reduce CO2 emissions and water usage in the next fiscal year.

Total CO2 Emission and CO2 Emissions per Sales (Akebono Brake Group Worldwide)

Water Usage and Water Usage per Sales (Akebono Brake Group Worldwide)

Contribution to the Realization of a Recycling-oriented Society

The Akebono Brake Group will keep contributing to the creation of a recycling-oriented society and will continue to pursue efficiency improvements in the use of recycled resources as well as reduction of waste disposal costs and optimization of disposal methods. In addition, we keep strengthening our efforts to achieve the goal of no emissions while further promoting “reduce, reuse, recycle” - the basic objective behind the zero-emission concept.

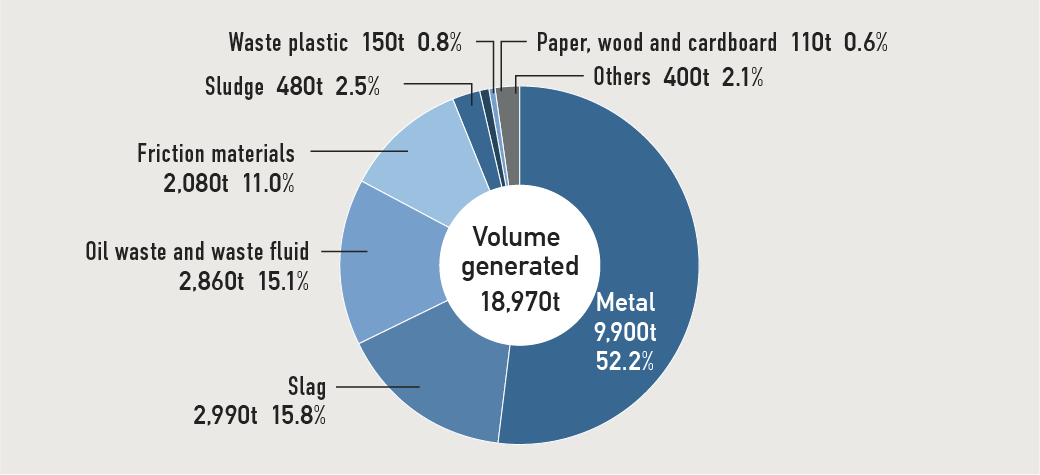

Waste Generated in Fiscal 2024 (major operations in Japan)

Fiscal 2024 Volume of Waste Generated and Recycling Ratio (major operations in Japan)

- * Since fiscal 2007, we eliminated landfill waste completely.

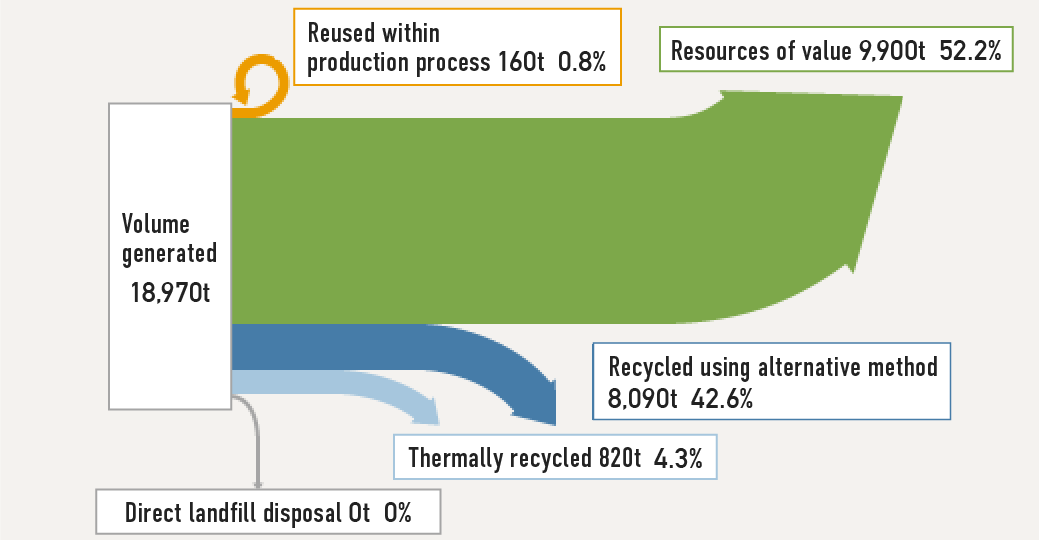

Change in Total Volume of Waste Generated and Total Volume Generated per Sales (major operations in Japan)

- * Total volume of waste generated includes resources of value, such as metals.

SQDCE*1 Improvement Activities

Since fiscal 2019, we have been engaged in "SQDC activities," focusing on ensuring safety and quality while striving to meet delivery deadlines and reduce costs. Starting in fiscal 2022, we added "E: Environment" to these activities, renaming them as "SQDC+E Improvement Activities," and have been putting more effort into environmental initiatives such as SDGs and carbon neutrality. Based on the "5-Gen*2 attitude, monthly follow-up meetings are held at each plant in Japan as one of the activities related to C, "Cost," and improvements are promoted focusing on issues from the production floor.

In the follow-up meetings, people from other divisions also participate to share their issues and cooperate with each other to solve problems that cannot be solved by the Manufacturing Division alone, leading to company-wide improvement activities.

One of the aims of our activities is to develop human resources who can solve problems through a sequence of processes and who can proactively identify issues and execute tasks through a bottom-up approach.

*1 SQDCE ... S: Safety, Q: Quality, D: Delivery, C: Cost, E: Environment

*2 5-Gen ... Genchi, Genbutsu, Gennin, Genri, Gensoku: Go to the actual place, see the actual things and confirm the actual facts. Then take action based on fundamental theory according to decided principles.

Introduction and Enhancement of Wastewater Treatment Systems

The Akebono Brake Group has introduced and enhanced wastewater treatment systems and is promoting environment-friendly production activities.

In fiscal 2020, Akebono Corporation (Guangzhou) achieved certification by the Environmental Impact Assessment Agency (EIA) after meeting strict effluent standards with the introduction of a new wastewater discharge station.

Furthermore, we are striving to further strengthen environmental management efforts by introducing online water quality monitoring system in fiscal 2021.

In fiscal 2020, Akebono Corporation (Suzhou) introduced automatic water quality measuring equipment and an online wastewater measurement system to strengthen wastewater treatment management.

Furthermore, in fiscal 2021, we installed wastewater vacuum evaporation and drying equipment and modified the water quality control tank, implementing management based on voluntary standards that exceed legal requirements.

Establishment of production lines that take sustainability into consideration for manpower, machines and materials

When designing production equipment, dies, jigs and other tooling, the Production Engineering Department is aiming for reusable designs as well as designs with high material yield, low energy consumption, and consideration of environmental impact.

1. Manpower savings through automation

We are focusing on promoting automation of production lines. In addition to anticipating a future shortage of human resources, we are contributing to the reduction of energy consumption for lighting, air conditioning, etc. through manpower reduction.

2. High-yield production line design

We are working to improve material yields in machining and casting processes through the use of CAE. We are also working to reduce energy consumption by establishing lines with high operational availability that do not produce non-conforming products.

Most recently, we have been focusing on production lines that achieve energy savings and reductions in CO2 emissions by consolidating processes.

3. Other steady activities

- Reducing energy consumption through the electrification of actuators, adoption of high-efficiency equipment, and the use of highly insulated materials

- Replacing tasks such as carrying, lifting, and moving heavy objects with robots or automated equipment wherever possible to reduce the workload on operators